The proper installation and leveling of CNC machines are important steps that go directly to performance, accuracy, and longevity. When installing it for the first time or relocating to another location, you can take that extra time doing the right thing: installing and leveling properly using best practices. Let’s dissect the process into manageable steps.

Pre-Installation Preparation

There is a little preparatory work that should be done prior to the CNC machine tool installation. For instance, it should ensure that the area where the machine will be held up all conditions:

- Environmental Conditions: Most CNC machines do not like the natural environmental conditions; they react adversely to temperature, humidity, and dust. The installation area should thus provide it with as much ventilation since unequal temperatures can cause distortion on the parts while high moisture destroys the accuracy of the machine.

- Flooring and Foundation: The place where the CNC will be stationed has to be firm and level. For the heavier CNC machines, concrete floors are the preferred choice since they minimize vibrations and due to the stability they would impose. The foundation should assure support for the weight of the machine, without possible settlement or shift over time.

- Power Supply: The power supply shall be of choice to suit the requirement of the machine in terms of voltage, amperage, and frequency. Beyond this, it requires proper grounding to avoid any electrical noise that would interfere with the operation of the CNC machine.

Machine Tool Installation

After the site preparation, the time is to move on to the actual CNC machine tool installation.

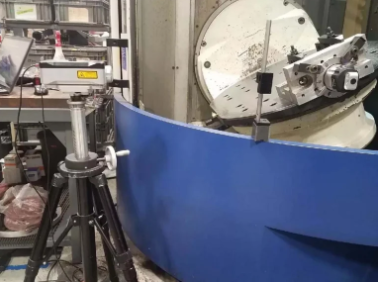

- Positioning the Machine: Placement of the CNC machine in the installation location can be done by a forklift or other equipment for lifting. The lifting of the equipment should be handled with care by adhering to all the recommendations of the manufacturer as there are areas that might contain some sensitive components which can easily be damaged.

- Anchoring: Anchoring is one of the several requirements for anchoring some CNC machines to the floor for added stability. An installation of bolts on the floor can reduce vibration, hence increasing the cutting precision and increasing the longevity of a machine. However, the alignment should be accurate before anchoring to avoid any alignment trouble.

- Assembling Components: Many CNC machines shipped come into operation with parts removed. Ensure you carry out the manufacturer’s assembly instructions to assemble the machine in the right manner. All attached parts must be firmly tightened and placed in their correct position.

Leveling the CNC Machine

One of the critical stages of installing a machine is leveling. Misalignment by as little as 0.5 mm can lead to inaccuracy in the machining operation and premature wear on parts of the machine.

- Why Leveling Matters: Levelling ensures that the weight of the machine is evenly spread across its supports and thus prevents internal stress. Internal stress may have effects on the cuts made such as producing skewed cuts that affect the quality of the final product, thus lowering the lifespan of the machine..

- Leveling Tools: For leveling, a precision spirit level or laser level should be mainly used. In general, these tools should give the precision required for CNC machine leveling to ensure they are perfectly horizontal.

- Leveling Process: Check the level by placing the level on the base or table of the machine and reading off the measurements. If the machine is out of level, readjust the leveling feet or shims under the base of the machine to orient the machine correctly. Be sure that the check is in both front-to-back as well as side-to-side angles to level the machine completely.

Calibration and Testing

After the installation and levelling CNC machine, it will be necessary to calibrate it. Calibration refers to the process where the position of different components on the machine, like the spindle, is adjusted properly in order.

- Initial Calibration: After the leveling process, run the machine’s calibration routine, which checks for mechanical alignment issues. This step may involve making fine adjustments to the machine’s axes and testing its accuracy through trial cuts.

- Operational Testing: After calibration, the machine should be tested with a sample project to ensure that everything operates smoothly. Test the machine’s full range of motion to detect any abnormal vibrations or noises.

Conclusion

Installing a CNC machine and leveling it is an intricate task that requires utmost care to attain maximum accuracy and performance. Installation, position, leveling, and calibration should be followed for elongation of the use time with maximum quality and top-tier accuracy in operations. Proper preparation would avoid future problems and minimize downtime, therefore optimizing machine productivity.